New Dimensions in Health Care: 3D printers offer economy, new products and jobs

Footpaths, not roads, connect villages in the Nuba Mountains in South Kordofan, Sudan, and motor vehicles are scarce. But there is a 3D printing lab. The region is officially a war zone, caught in the conflict between Sudan and the new South Sudan. It’s there that the California-based technology company Not Impossible established a prosthetic printing facility to assist the growing number of amputees.

Project Daniel, named for a teenage boy who lost both of his arms to a bomb attack, fitted its namesake with a printed RoboHand prosthetic in late 2013. Since then, local trainees have printed and fitted two more prostheses after the lab’s founders left the operation in their charge.

As an oasis of new technology in the agrarian communities the lab seems like a nonsequitor. As critics may point out, it owes its existence to the world outside of Sudan as a technology transplant in a lesser developed region. But 3D printing may hold promise in the developing world, and it may be catching on.

To make something, 3D printers melt a filament, which is usually plastic, but it can be of a soft metal or even a food like chocolate. Then they deposit it, stacking layer upon layer to gradually build an object.

The technology leapfrogs some problems more cheaply than traditional methods. There are few roads in the Nuba Mountains, but printing things reduces the need for delivery. Printing also reduces waste and saves money. In 2013, a research team at Michigan Tech found that printing things is both cheaper and consumes less energy than paying for them. In time, printers in remote regions may manufacture parts to repair other devices, create new products and, of course, jobs.

“There is a lot of talk about 3D printers and the time is very ripe for this gadget to explode on the scene.” – Dhananjay Gadre, ECE professor at the Netaji Subhas Institute of Technology in New Delhi, India

“3D printing is something that has definitely taken off in South Africa. As for most of Africa that will take some time. But it will certainly get there. Let’s give them a year,” Richard Van As, the South African who invented the Robohand and trained Sudanese technicians to print the prosthetic, told Engineering for Change.

“Teaching the guys, I saw a bit more than excitement. Passion to help the less fortunate far exceeded any effort or exhaustion. I would say that anything one could try to do to stop it would be futile,” Van As says.

Not Impossible brought Van As together with an international team to launch its lab. But fans of 3D printing and other rapid prototyping tools can pool their knowledge in less formal ways. Low-cost communications make it happen through wikis and other shared documents, text messages, VOIP calls and so on. Those work because of the famously generous spirit of open source communities. The worldwide 3D printing community seems to bend toward open source tools and donated time for support. (To get started, see tips for rapid prototyping with 3D printers.)

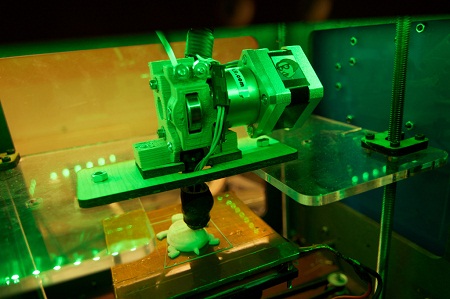

(Some Fab Labs like this one in Durham, N.C., (left) provide 3D printers for rapid prototyping and small-scale manufacturing. Photo by Keith Kissel / Flickr)

At the moment, and as far we can tell, most 3D printers in developing countries remain confined to engineering departments at technical universities and specialized workshops such as Fab Labs. Fab Labs, an extension of MIT’s Center for Bits and Atoms, provide tools to prototype inventions and stimulate local entrepreneurship. Nearly 130 are up and running worldwide, many of those in Africa, India, Southeast Asia and Latin America.

A printer layered plastic into clear candle-flame shaped LED bulb housings in Dhananjay Gadre‘s Fab Lab at the Netaji Subhas Institute of Technology in New Delhi, India. Gadre, a professor of electrical and computer engineering, designed an LED lantern that mimics a flame and even turns on when touched with an electronic “matchstick.” That’s just one of his printed projects in a lab equipped with other prototyping tools, including a Shopbot Desktop milling machine. Gadre is not aware of other 3D printers nearby, but he thinks that might change.

Related article: Body Parts on Demand: Will 3D printing spark the next revolution in BoP health care?

“I have heard some elite schools in this region have it but I cannot vouch for it. There is a lot of talk about 3D printers and the time is very ripe for this gadget to explode on the scene and suddenly a lot of people could acquire one,” Gadre says. In fact, he has been predicting their popularity for a while, he says.

Back in South Africa, Van As has been drumming up financial support and donations for his printable RoboHand prosthetic. He seems equally as optimistic about the printer’s prospects.

“3D printing is certainly a great buzz and I think it will last for a good while to come. It seems that it may also become part of the education systems in the schools all over the world,” Van As says.

Rob Goodier is the managing news editor at Engineering for Change.

The story originally appeared on Engineering for Change’s Health blog, and is shared through a media partnership between NextBillion and E4C.

- Categories

- Health Care