Lean Thinking isn’t Just for Large Manufacturing Businesses: A Roadmap for Applying it to Small and Medium Enterprises

Toyota pioneered the Toyota Production System lean thinking practice — a rigorous, data-centric approach that aims to improve operations by optimizing business processes and empowering staff to identify and solve problems — in the 1950s. But lean thinking doesn’t just apply to manufacturing giants. With the goal of continuously improving the quality of products and services, the methodology can be valuable to businesses of any size, across sectors and geographies. And with its focus on reducing costs and increasing customer satisfaction, lean thinking can improve both profits and stakeholder well-being.

The use of lean approaches among small and medium enterprises (SMEs) and across the nonprofit sector is increasing. It’s a growing part of our work at the William Davidson Institute at the University of Michigan (WDI). Our team within WDI — Performance Measurement and Improvement — applies lean thinking during impact measurement and continuous improvement projects to unlock financial and social benefits for our partners. These partners include both profit-seeking and non-profit firms that leverage business tools to increase economic and social prosperity in low- and middle-income countries. To take just one example of this work: In a virtual exchange program led by WDI, we applied lean thinking tools to increase student survey response rates. Our goal was to ensure that we gathered sufficient critical feedback to make changes to the course in each subsequent semester (continuous improvement), in order to better develop cross-cultural understanding and collaboration among enrolled students.

In the article below, we’ll introduce readers to lean thinking and its benefits for SMEs, define key concepts and standard practices that form its central tenets, share popular problem-solving tools that can help identify process efficiencies, and propose a roadmap for applying lean approaches in business operations.

An Introduction to Lean Methodologies

Lean thinking is a management philosophy that can be summed up as “doing more with less.” Lean methodologies can offer many benefits to businesses. They can increase customer satisfaction, reduce costs, improve the quality of products or services and reduce their time-to-market, improve employee skill development, and enable companies to quickly adapt to external changes. Lean practices deliver these benefits by fostering a culture of continuous experimentation in a business, aimed at maximizing efficiency by creating value with fewer resources and less waste.

Waste is defined as any action or step in a business process that does not add value to the customer. There are eight kinds of waste addressed by lean thinking: defects, overproduction, waiting, unused talent, transportation, inventory, motion and extra processing. Among these, the most well-known are: waiting (e.g., time spent waiting for materials for production, information from suppliers, approvals from managers, etc.), defects (products or services that do not meet customer requirements), and inventory (excess products or materials).

To identify areas of waste, lean thinking establishes a standard for every business process that compares abnormal and normal results. It also includes procedures to improve existing processes or develop new products/services effectively and efficiently. If the standard doesn’t produce the expected result with minimal waste, lean methodology prescribes a set of practices and tools to enable the business to experiment with potential solutions.

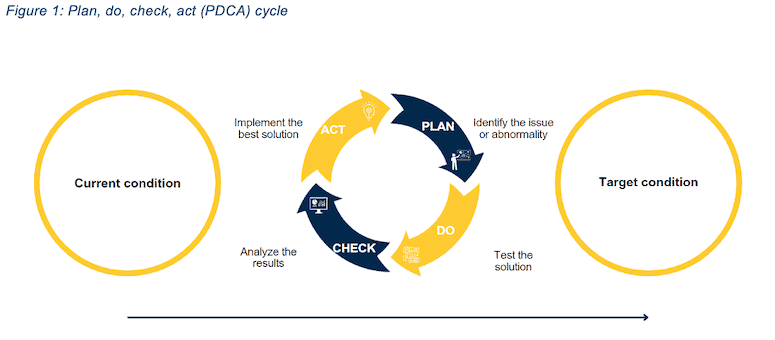

The foundation of these experiments is the “Plan, Do, Check, Act” (PDCA) cycle. In the Plan stage, a business runs diagnostics to identify gaps and abnormalities in its processes, defines its goals, and develops an action plan. In the Do stage, it moves into action, pursuing the goals and tasks it has defined through an experiment. This is followed by the Check stage, in which the business assesses the improvements it has made by analyzing the results of the experiment. Finally, in the Act stage, it implements the solution and continues applying PDCA to identify new potential issues. The PDCA cycle is meant to be repeated again and again for continuous improvement. It provides a simple and effective approach for solving problems and managing change, whether for an entire project or a small task within the project (See Figure 1 below).

Key Lean Thinking Tools

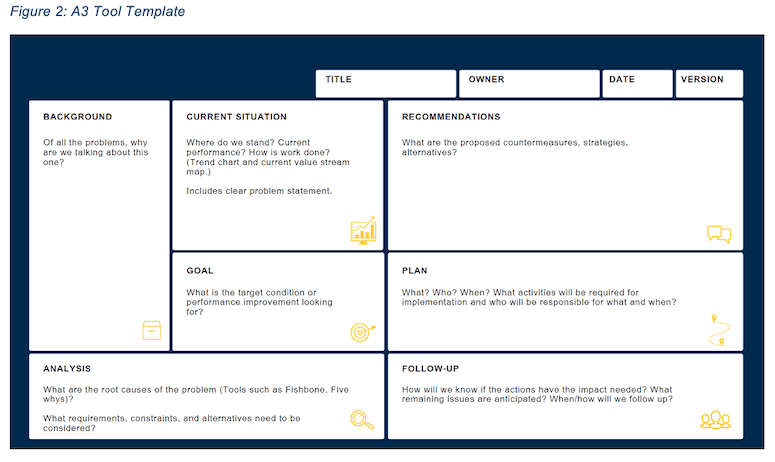

Several popular lean thinking tools can be used throughout the PDCA cycle, including A3 problem solving, in which all the key information about a problem and its potential solutions fits on an 11×17 inch piece of paper. The beauty of the A3 approach is that it tells a concise story about a business problem, laying out an entire plan to solve it or make a related improvement on a single piece of paper (See Figure 2).

The value of the A3 tool lies not in the format, but in the process and thinking behind it. An A3 approach can help make the case for change or experimentation, while providing a way to create understanding to lead to action, and encouraging managers and leaders to observe operations and engage with employees. Thus, A3 thinking works both as a problem-solving tool and a structured process for developing proficient problem-solvers within an organization.

You can learn more about the A3 approach in this recording of WDI’s lean thinking webinar, held in October 2023, in which we walk through an example of how the A3 tool was used in a garment factory in India. Other popular lean tools include the fishbone, five whys, value stream maps (additional resource), and process maps (additional resource). Process maps are also discussed in our webinar recording, where a colleague from WDI’s Healthcare team shares how he created a process map of all the steps and decision points in an eye surgery clinic in Mexico, in an effort to calculate and reduce the company’s process costs.

A Roadmap to Apply Lean Thinking in Your Team

Despite its many benefits, lean thinking does present some challenges. For instance, it requires a cultural shift because of its focus on involving staff — instead of just management — in identifying problems and testing solutions. It necessitates a commitment to observation and collaboration, both of which require staff and management time. It also requires that teams avoid the “blame game,” in which they spend valuable time trying to assign (or avoid) responsibility for the inevitable shortcomings identified by the lean approach.

We acknowledge that lean thinking can generate resistance to change, but there are ways to address this. The following roadmap presents small, incremental steps businesses can take to begin to apply lean practices, gather organizational champions to support these changes, and develop buy-in for this methodology with leadership if they are unfamiliar with the approach and its value-proposition:

- Start by identifying a standard for a key problem or process. It can be an administrative process like customer service, or a manufacturing process. If a standard doesn’t exist, create one based on target benchmarks of costs and time for each step in the process. You can also develop benchmarks based on historical context or company goals. There is a tendency to want to start with extensive training for your team on lean thinking, but this can involve a major investment of time and money. Instead, it is more valuable to learn the basics and get started: By identifying a process that would benefit from such a review, you can start your lean thinking journey, developing your skills as you apply and practice these methodologies.

- Next, involve the team in identifying waste in the process, through the use of lean tools. For example, the team can create a value stream map — essentially a flowchart — for the targeted problem/process, and lay out its current steps. Next, the team can use an A3 problem-solving tool to create a hypothesis for how to eliminate the waste it has identified to create a better product or service for the customer. When applying these tools, managers should not tackle the problem themselves; instead, they should lead a collaborative effort to find solutions together with their teams, ensuring team empowerment and skill development at all staff levels. To that end, managers should model problem-solving and facilitate and support the flow of information, especially across teams. Furthermore, they should ensure that a timely and positive response is made to staff who identify issues, to help incentivize this key behavior.

- Launch experiments and implement the PDCA cycle. Based on the findings, you can make changes to products, services and operations in real-time. Additionally, sharing the results of the experiments — and highlighting changes in key quantitative metrics such as lead time — can achieve quick wins and build buy-in for the continued use of lean practices and tools.

- Identify champions and make the case to leadership (if needed), highlighting the value generated by lean approaches (e.g., higher sales, lower costs, more engaged employees). Seek sustained buy-in and resources for using lean practices.

- Formalize a continuous improvement agenda. Such an agenda can help prioritize the application of lean thinking to key processes in the company’s broader strategy. The agenda also helps ensure that the knowledge gained through lean thinking activities is disseminated within the company, creating a virtuous loop.

At WDI, we use lean tools to help our partners diagnose problems, develop hypotheses, and test and evaluate those solutions. We hope this article piqued your interest in lean thinking, and that you are ready to start a conversation about this approach with your team. If so, we’d be happy to discuss these practices further with you. You can reach us at WDI-performancemeasurement@umich.edu.

Yaquta Fatehi is a program manager and Heather Esper is the director at the Performance Measurement and Improvement Initiative at the William Davidson Institute (WDI) at the University of Michigan. WDI is NextBillion’s parent organization.

Photo courtesy of Jason Goodman

- Categories

- Uncategorized